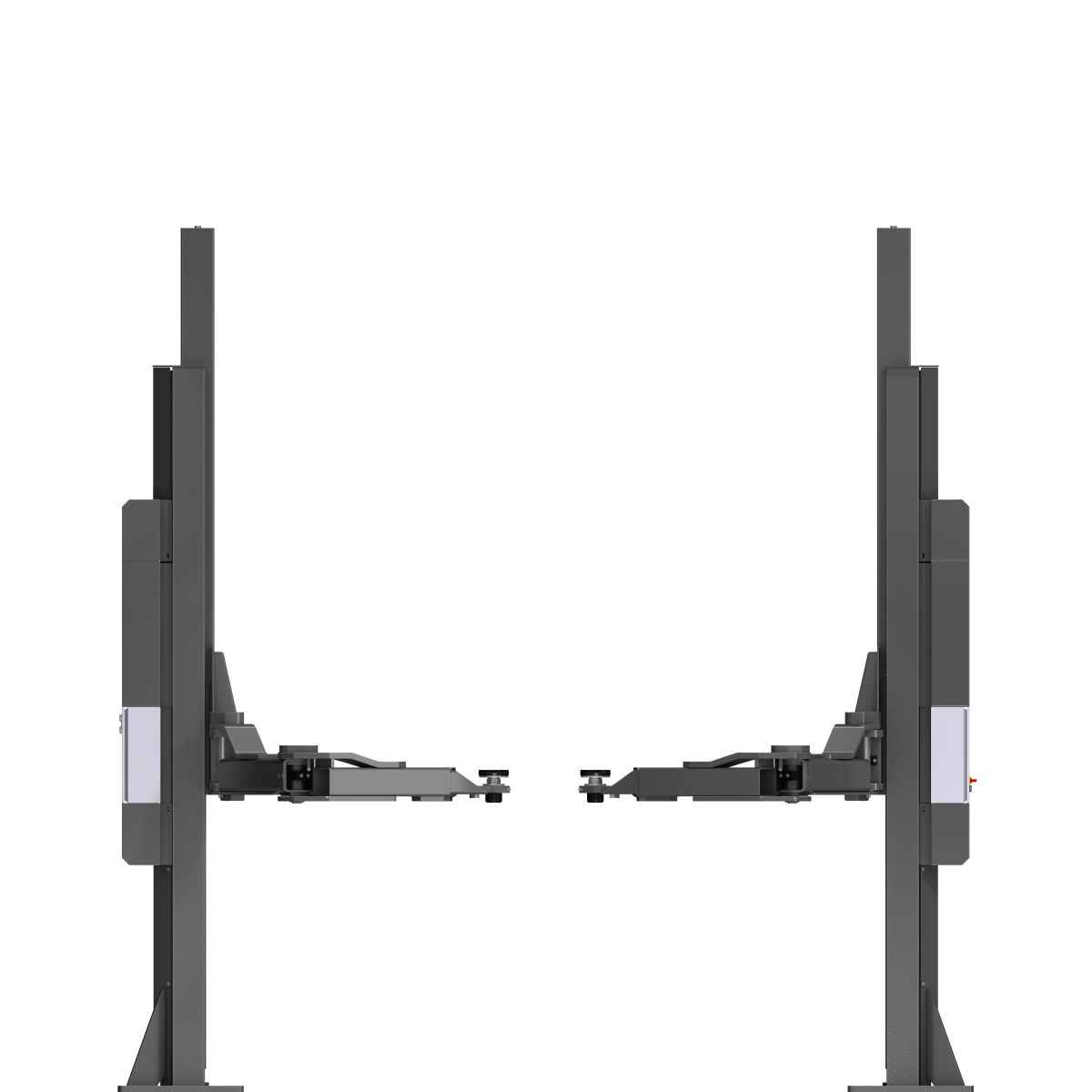

POWER LIFT HDL 7500 SST DG

Hydraulic 2-post lift with double jointed arms

POWER LIFT HDL 7500 SST DG

Item No:HDL275.4001024D-7016

Customize

Compare

Brief description

Item No:

HDL275.4001024D-7016

Lifting capacity:

7500 kg

Type

2 post lifts

Color

Grey

Händler in Ihrer Nähe

43

Nicht Ihre Postleitzahl? hier eingeben

Weitere Händler

Nussbaum Automotive Lifts, Inc.

177 Defense Highway Suite 7, Annapolis

Maryland 21401

https://

| Capacity | 7500 kg |

|---|---|

| RAL color | RAL 7016 - grey |

| Pick up pad height min | 147 - 222 mm |

| Min length front arm | 0 - 1833 mm |

| Min length rear arm | 0 - 1833 mm |

| Lifting time | 46 sec |

| Lowering time | 55 sec |

| Lifting height max. | 2127 mm |

| Required ceiling height | 4405 mm |

| Total height min | 4540-4990 mm |

| Total width min | 3570 mm |

| Clear distance between columns min | 2513 - 2765 mm |

| CE-Stop | ja |

| Electrical connection (Ph/V/Hz) | 3 Ph , 400 V , 50 Hz |

| Fuse protection | |

| Engine power | 2X3 KW |

Datasheets

| Data sheet HDL 7500 SST DG | 390 KB |

Force Diagrams

| Force diagram HL 7500 / HDL 7500 SST DG | 71 KB | ProductDataTabs

Dowel drilling patterns

| Dowel hole pattern HL / HDL SST | 35 KB |

Liftingpatterns

| Pickup point matrix HL / HDL 6500 7500 9000 SST DG | 116 KB |

Inspection books

| Power Lift HL HDL 6500 7500 9000 SST DG | 20 MB |

Leaflets

1

| Packaging | |

|---|---|

| Product Dimensions | 3100mm x 1000mm x 1100mm |

| Total weight | 950kg |

| Stackable |

1

| Packaging | |

|---|---|

| Product Dimensions | 3100mm x 1000mm x 1100mm |

| Total weight | 950kg |

| Stackable | Not stackable |